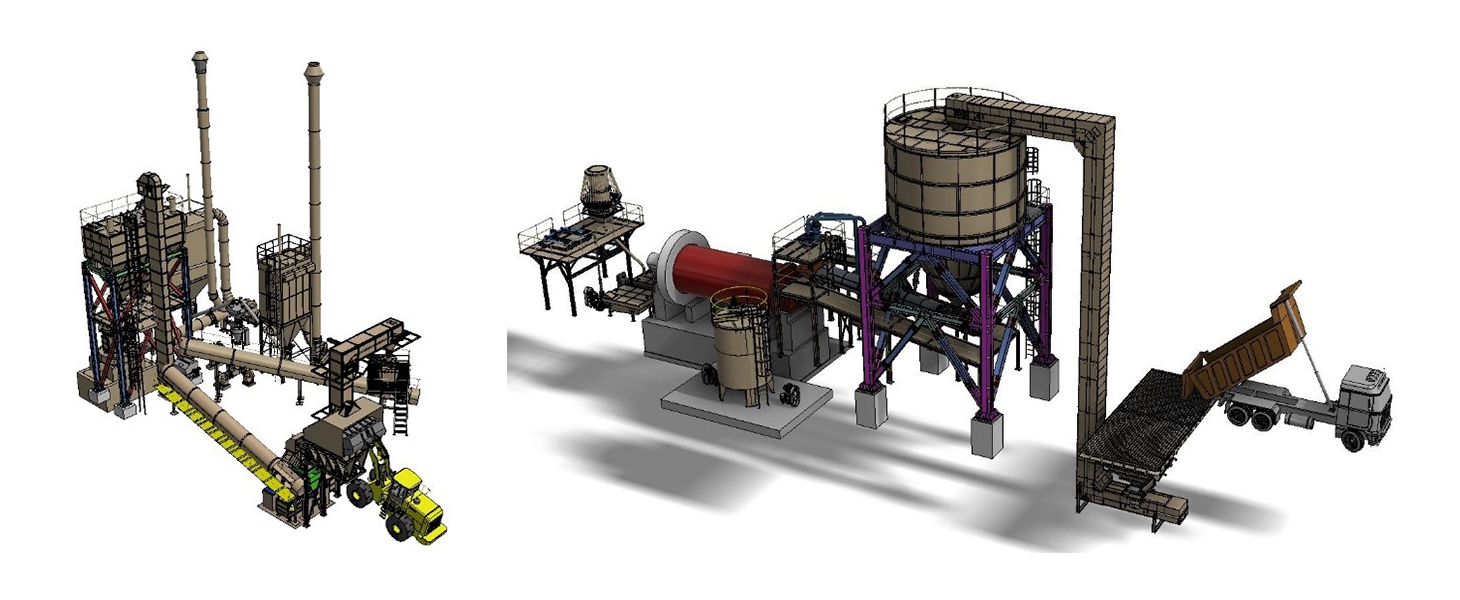

Turn-Key Solutions

As Ente, we have been expanding our scope of turnkey projects and our team since the day we were founded, and transforming the facilities we have created virtually into reality.

We apply the turnkey concept in new projects as well as in expansion, revision and efficiency projects.

Project Design & Engineering

Project design and engineering comprises also expansion, revision and productivity projects. Our project design and engineering unit consist of mechanical, material and civil engineers. We study on projects 3D basis in order to improve plants in the following aspects.

-

Process safety

-

Process efficiency

-

Operability

-

Maintainability

We study on process safety and improve special designs in order to avoid any damage during production. We design production process as per material physical and chemical properties and design equipment accordingly.

With complete design building, structure and equipment, we create easy to operate production plants.

For long life time of the plant maintenance is very important and we always take care about easy maintenance and availability of system instruments in our designs. Also for safe maintenance we put switches on site to interrupt connections.

Manufacturing

After the preparation of all manufacturing drawings of the facilities whose designs have been completed, we make resource planning in accordance with the project schedule. We produce in our manufacturing factory with a closed area of 3000 m2 and supply complementary equipment and produce facilities on time and in accordance with the budget.

We produce structural steel construction for plant buildings as well as production towers and platforms. Steel construction unit capacity is 500 tons steel per month. We will reach 800 tons per month with second step of our investment.

Based on engineering department shop drawings or customer project drawings we manufacture industrial equipment.

-

Feeding hopper

-

Vibrating feeder

-

Raw material and product silos

-

Belt conveyor from 0 to 90 degree conveying

-

Screw conveyors (cylinder or U type)

-

Bucket elevator

-

Additive hopper with dust suction design

-

Weighing hopper

-

Kraft bag and bigbag unloading station

-

Liquid tanks

-

Mixing Systems

-

Jetpulse filter

-

Ductwork

-

Project based manufacturing

Together with our domestic and foreign partners for equipment supply, the selection of the most suitable equipment and instruments for the designed process is made by our engineering team and we are integrated with our factory productions and shipped to the factory site ready for assembly.

Assembly & Start-Up

With our experienced assembly team and commissioning engineers, we integrate the facilities that we have completed the mechanical and electrical assemblies in the field in accordance with the occupational safety rules into the automation system and commission them to meet the desired capacity and sensitivity values. Thus, we deliver the facilities to our customers in a smooth and continuous working condition.

Automation

In accordance with the process design, we prepare P&ID diagrams that include process flow, process equipment and automation instruments, we create facilities that work with full automation by preparing process operating scenarios.